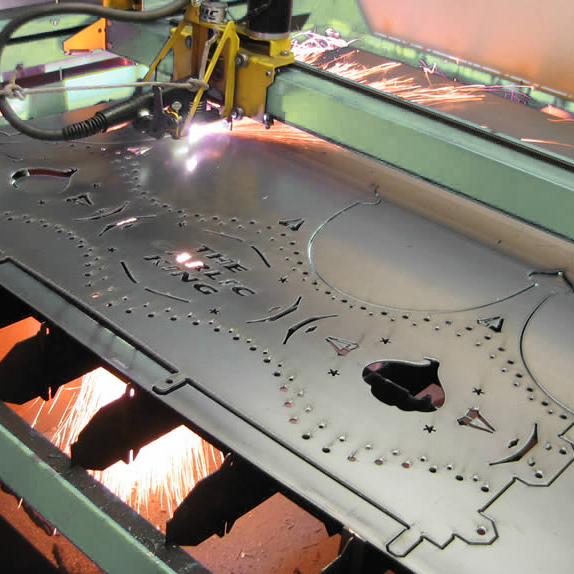

We use in the production of metal pieces high-performance plasma machinery. Plasma cutting is a heat induced cutting process using a short-arc cutting process plasma arc. The arc is created when electric current flow is moving from cathode (non-melting electrode) to the anode i.e. cutting piece, electrically conductive.

The energy needed to melt the work piece is provided by the plasma jet and the electric arc. The plasma gas is partially dissolved, it is ionized and converted into electrical conductor – then energy density and high temperatures is moving towards the work piece with a multiple speed of sound. When the thick plasma jet of high-energy reaches the work piece surface, the molecules come together again so that the energy stored and released from the arc partially melts and evaporates the material. In addition, large kinetic energy of plasma beam allows the evacuation of molten material. This process is extremely efficient and provides excellent quality work.